Microgravity Manufacturing: Producing Nanomaterials That Could Revolutionize Medicine

Axiom Space astronauts Peggy Whitson and Rayyanah Barnawi producing the Janus base nano-matrix for the first time on station.

Media Credit: Axiom Space

March 25, 2025 • By Amelia Williamson Smith, Managing Editor

In Roman mythology, Janus is the god of endings and new beginnings. He is usually depicted as having two faces—one looking to the past and the other to the future. In his hand, Janus holds a key, symbolizing his power to unlock doors to new possibilities.

When Yupeng Chen and his team at the University of Connecticut developed synthetic molecules that self-assemble into nanomaterials that could revolutionize drug delivery and lead to new treatments for osteoarthritis and cancer, the Roman god immediately came to mind. Like Janus, the molecules have two faces, allowing them to bind together in a way that mimics DNA. To further develop Janus base nanomaterials (JBNs) as commercial products, Chen and his colleague Mari Anne Snow co-founded Eascra Biotech, a spinoff from his University of Connecticut lab.

Eascra’s JBN products performed well but had slight defects. Janus base molecules first self-assemble into rings that then stack like dinner plates to form nanotubes. Gravity-driven forces like convection cause the molecules to aggregate in some places as they assemble into the rings, which reduces the uniformity of the nanotubes. The imperfections frustrated the team, but they didn’t know what to do.

Then, as if Janus stepped in with his key and opened the door to something they never imagined, Chen and Snow came upon a possible answer—manufacturing their nanomaterials in space.

They had read about others who leveraged microgravityThe condition of perceived weightlessness created when an object is in free fall, for example when an object is in orbital motion. Microgravity alters many observable phenomena within the physical and life sciences, allowing scientists to study things in ways not possible on Earth. The International Space Station provides access to a persistent microgravity environment. on the International Space Station (ISSInternational Space Station) to produce more uniform and well-ordered protein crystals than can be produced on Earth. They wondered: Could microgravity similarly improve nanomaterial assembly? To find out, Chen’s lab and the Eascra team conducted a series of investigations sponsored by the ISS National Laboratory®.

“We started thinking about how we could better form the nanomaterials, and producing them in microgravity could be a solution,” Chen said. “If in-space production could give us nanomaterials with better structure, integrity, and uniformity, it may also give us better bioactivity and therapeutic outcomes.”

Reconstructing Cartilage at the Nanoscale

The first project from Chen’s team, funded by the U.S. National Science Foundation, launched on Northrop Grumman’s 20th Commercial Resupply Services mission(Abbreviation: CRS mission) A CRS mission is a cargo resupply mission contracted by NASA to deliver supplies and research to the International Space Station on commercial spacecraft as part of the CRS contract with three commercial companies. As part of CRS missions, experiments currently return to Earth on SpaceX Dragon spacecraft that splash down in the ocean. for NASANational Aeronautics and Space Administration. The aim wasn’t to manufacture JBNs but to test their effectiveness for cartilage regeneration.

Cartilage is the tough, flexible tissue that pads joints. For people with osteoarthritis, which affects one in seven Americans, cartilage in joints like the knees and hips slowly breaks down over time, which causes pain and inflammation.

Because cartilage has a limited blood supply, it does not regenerate well, so it isn’t easy to restore once it is gone. Currently, the only long-term solution for osteoarthritis is expensive joint replacement surgery with a long and painful recovery. In the United States, nearly 800,000 knee replacements and more than 540,000 hip replacements are done every year. The JBNs developed by Chen and his team could be a game-changer by providing a way to rebuild lost or damaged cartilage.

Yupeng Chen and graduate students Ian Sands and Anne Yau prepare their experiment for launch on NG-20.

Media Credit: University of Connecticut

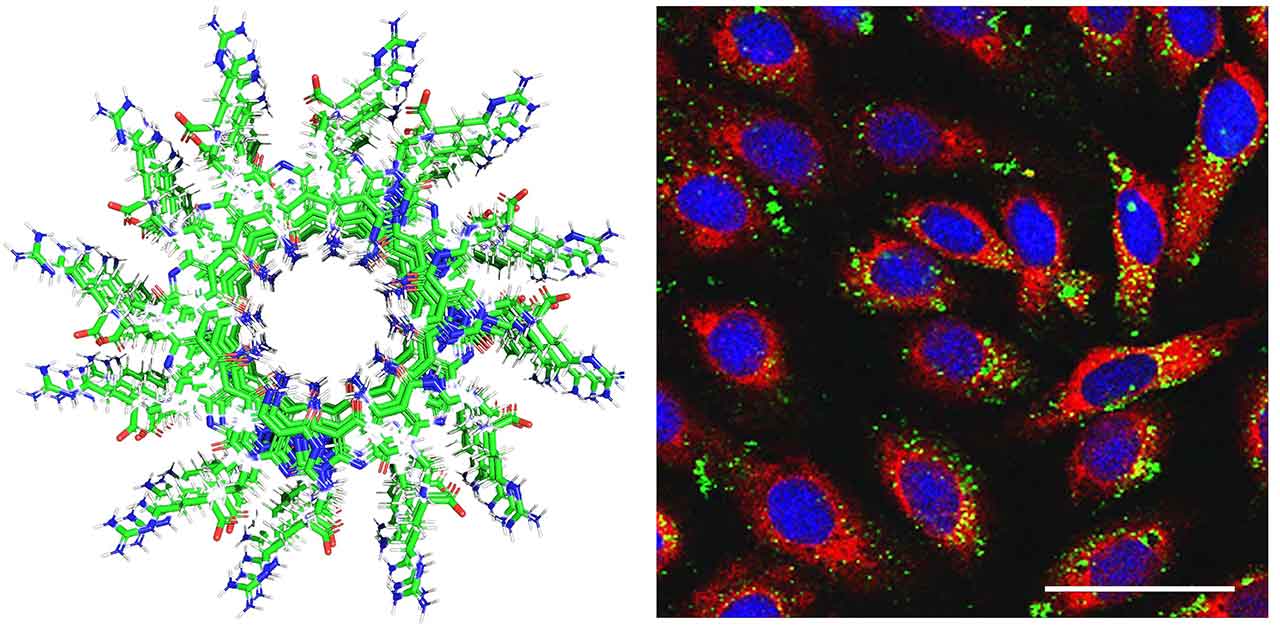

The team’s Janus base nanoparticles, which are 1,000 times smaller than a cell, can carry therapeutics into hard-to-penetrate tissues like cartilage. The nanoparticles can be loaded with an RNA-based drug that stops cartilage breakdown and stimulates cell formation. RNA drugs cannot pass through the cell membrane of cartilage cells, but the nanoparticles can, making them the perfect delivery vehicle.

The team also developed a Janus base nano-matrix to support and maintain cartilage cell growth. You can think of the nano-matrix as scaffolding for building construction, said Max Landolina, a graduate student at Chen’s lab. “When we put up the scaffold, all the workers, the cells, are attracted to it and go there to get set up,” he explained. “Once they have that good foundation, they can start to rebuild and create new structures.”

The nanoparticles and nano-matrix are both flexible and can be injected into affected joints. The JBNs’ ability to fit into every corner of an irregularly shaped defect to regenerate cartilage results in a better repair outcome, Chen said. The JBNs are also stable at room temperature. This means they do not have to be kept at sub-zero temperatures like other RNA-based drugs that immediately degrade in ambient conditions. Because refrigeration is not required, it is much easier to ship the JBNs to different locations around the world and store them for use.

Left: A cross section of a Janus base nanotube with a diameter of 3.5 angstroms. Right: Green-fluorescence-labeled RNA drugs were delivered into human cartilage cells by JBNs (scale bar is 100 micrometer).

Media Credit: Maxwell Landolina, Trystin Cote, and Jinhyung Lee, University of Connecticut

In microgravity, cartilage degeneration happens more quickly than on Earth. So, the space station provides a valuable platform to test how well JBNs work. “By using disease models in microgravity, instead of waiting for years, we may just have to wait a couple weeks to see disease progression,” Chen said.

Housed in Space Tango’s CubeLab hardware, the team’s tissue samples—half treated with the JBNs and half not—remained on the ISS for 14 days before returning to Earth for analysis. The results revealed that the nanoparticles successfully prevented cartilage degradation and supported cartilage cell formation. The team also found that the nano-matrix significantly promoted cartilage regeneration and maintenance.

Becoming a Space Company

When Yupeng Chen came to the U.S. to pursue his Ph.D. nearly 20 years ago, Mari Anne Snow served as his cultural mentor through the International House.

Media Credit: Yupeng Chen

After the first successful project, the team’s mindset shifted to using microgravity to improve JBN production. “While we didn’t intend to be a space company, we’re actually the perfect candidate,” said Snow, CEO of Eascra Biotech.

Chen and Snow co-founded Eascra in November 2021, but the two have known each other for nearly 20 years. They met when Chen first came to the U.S. to pursue his Ph.D. at Brown University. Snow was part of a nonprofit called International House that provides cultural mentorship for international students pursuing graduate degrees in the U.S. and served as a mentor for Chen.

“We celebrated the holidays together and shared our different cultures,” Chen recalls. “I had my first Thanksgiving and Christmas with Mari Anne and her husband, and even today, we always celebrate Thanksgiving together.”

Over the years, Chen and Snow talked about one day partnering on a biotechnology startup, Chen with his biomedical science expertise, and Snow with her background in business and finance. When Chen and his team created and patented JBNs, the time had come, and Eascra was born.

At the time, Chen and Snow never dreamed that Eascra’s products would one day be manufactured in space. But after reading about other researchers’ successes, they were anxious to see if microgravity would improve the quality of their nanomaterial products. The team partnered with Axiom Space on two investigations sponsored by the ISS National Lab.

“Axiom Space is all about expanding access so anyone anywhere can leverage the unique space environment,” said Pinar Mesci, Axiom Space senior program manager and global head of regenerative medicine and disease modeling. “Microgravity research enables us to look at the same problem through a very different lens, and that’s where innovation happens.”

The first project, which was aimed at manufacturing Eascra’s Janus base nano-matrix, flew on Axiom Mission 2 (Ax-2). The experiment was simple: First, the astronauts added water into reaction tubes filled with a powdered form of Janus base molecules. They then added a protein solution and waited for the nano-matrix to self-assemble.

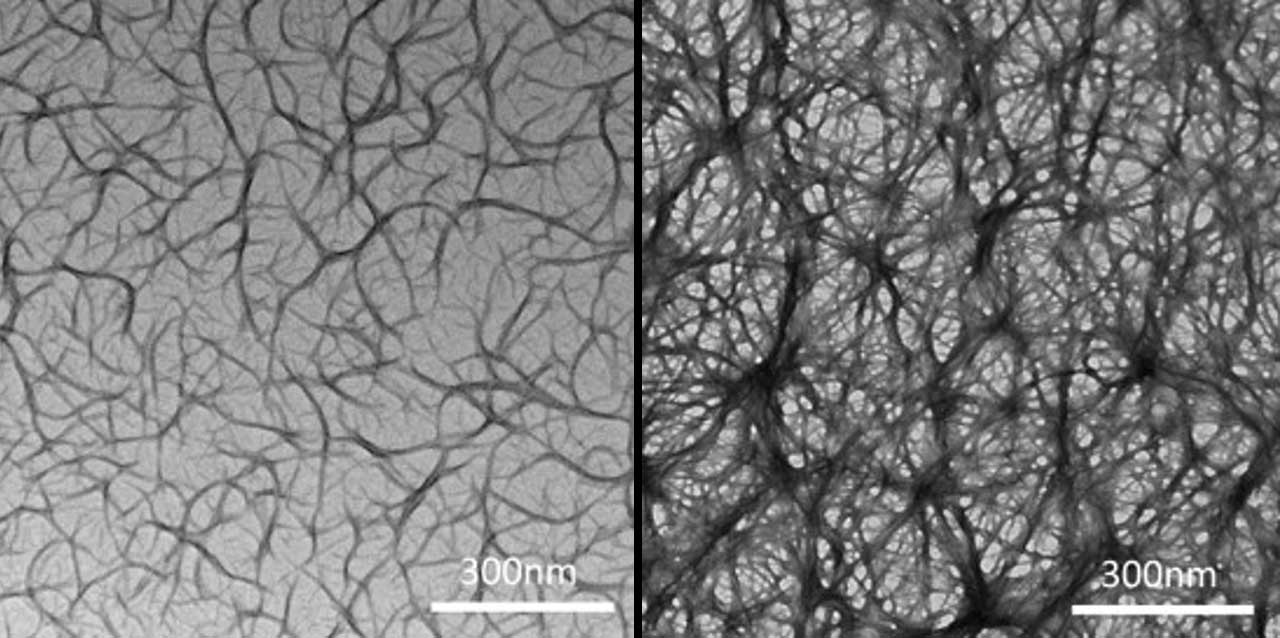

The samples remained on the ISS for two weeks before being returned to Earth. When Chen and Snow compared the space-manufactured nano-matrix with what they produced on the ground using the same methods and procedures, they couldn’t believe what they saw.

This image of the first Janus base nano-matrix produced in space (right) clearly shows the significant improvement in structure over the nano-matrix produced on the ground (left).

Media Credit: University of Connecticut/Eascra Biotech

“We discovered that in space, we were able to achieve huge gains in uniformity and homogeneity, with up to 40-percent improvement in the structure of the nano-matrix scaffold,” said Snow, beaming with excitement as she pulled up images from the investigation. “You can clearly see that the space-produced nano-matrix is structurally denser and stronger.”

With these results, Eascra’s future was clear. “That was the moment we became a space company,” Snow said.

For the next ISS National Lab-sponsored project, which launched on SpaceX’s 30th Commercial Resupply Services (CRS) mission for NASA, the team produced the nano-matrix and nanoparticles loaded with an RNA-based drug. The team also sent up a small UV spectrometer to characterize the JBNs in real time and a handheld sonicator, which uses sonic waves to agitate the nanomaterials and break them into smaller nanoparticles.

While the project was on station, the team watched via livestream. “My favorite part was coming into the lab at 2 a.m. to communicate with the astronauts while they did our experiments,” said Trystin Cote, a graduate student in Chen’s lab. “We could give them tips on how to work with our samples and help them in any way needed to improve the science.”

University of Connecticut graduate students Max Landolina (far left) and Trystin Cote (far right) work with Alexis Rios and Pinar Mesci from Axiom Space to prepare the team's SpaceX CRS-30 investigation.

Media Credit: University of Connecticut/Eascra Biotech

After two weeks in space, the JBNs were returned for analysis, and once again, the team was excited about the results. “In space, we were able to not only build nanoparticles with better structure but also encapsulate RNA, which is a very fragile cargo, in such a way that we can maintain its bioactivity at room temperature for months,” Snow said.

The team also found that the space-produced nanoparticles result in better functional outcomes when compared with those produced in the ground control. “The benefit we get from assembling our nanomaterials in space is unparalleled to what we can do on the ground,” Cote said. “Our Earth-made samples are already really good, so being able to advance them that much just by sending them into space is amazing.”

Refining Production and Scaling Up

Following these successes, the team was awarded two additional ISS National Lab-sponsored investigations funded by NASA to continue working with Axiom Space on the in-space production of JBNs.

Max Landolina, Maddie Picket, and Jared Lawrence (left to right) from the University of Connecticut prepare the team's investigation for launch on SpaceX CRS-31.

Media Credit: University of Connecticut/Eascra Biotech

“We were doing foundational work to get everything in place so we could start to expand quickly,” Snow said. “Our goal every single flight is to get closer to being production-ready and to optimize the formulation for commercialization.”

In the first project, which launched on SpaceX CRS-31, the team increased from 30 or 40 samples to 140 samples and from two to four weeks on station. The second project will launch on the upcoming SpaceX CRS-32 mission with the same sample size but fewer variables.

“We have refined our production procedure and verified that our nanomaterials can be better produced in microgravity, and we achieve not only better uniformity but also better bioactivity,” Chen said.

The team is now working to identify the best conditions for in-space production and develop an automated system to scale up. The ISS National Lab provides a critical platform to do this, Mesci said. “It’s where we conduct all types of proof-of-concept research to generate the data we need to go to the next steps where we can scale up the manufacturing process.”

The Eascra team is collaborating with Google to use machine learning and AI tools to better characterize JBNs and improve quality control. Chen said the team’s goal is to standardize production and quality control processes to comply with the requirements from regulatory agencies such as the U.S. Food and Drug Administration.

“Commercial companies like Axiom Space coming into this arena is important,” Mesci said. “We have to be able to meet commercial timelines to make products in a timely manner and make sure quality controls are still intact for regulatory approvals.”

Eascra is also expanding beyond osteoarthritis to cancer treatment. The startup received grant funding through the inaugural ISS National Lab Igniting Innovation solicitation, in partnership with NASA’s Biological and Physical Sciences Division, to produce Janus base nanoparticles for precision cancer treatment.

The nanoparticles can encapsulate cancer drugs and directly deliver them into dense solid tumors that are notoriously difficult to penetrate, Snow said. The nanoparticles also prevent the drugs from affecting other parts of the body, significantly reducing side effects. And because JBNs mimic DNA, the nanoparticles don’t trigger the immune system, which allows the drugs to remain at the tumor site for longer.

Yupeng Chen (left) and Mari Anne Snow (middle) with Eascra Biotech science advisor Gary du Moulin (right) when the company was named 2024 MassBioDrive Startup of the Year.

Media Credit: Eascra Biotech

“Drug discovery is not going to be effective if there’s not a way to deliver the therapeutic to the treatment site,” Snow said. “If you go to any major therapeutic conference, there’s lamenting about the fact that there’s not a good delivery system.” Eascra’s JBNs could be the solution for a wide range of therapeutics that need an effective delivery method.

Like Janus, Snow looks both to the past and to the future. “We’ve had a lot of ‘pinch me’ moments,” she said. “How many opportunities do you get in life to access one of the most extraordinary research environments that allows you to push the boundaries of what’s possible?”

Reflecting on the team’s space-based research, she describes the experience as incredible. Looking forward, she is excited about the future of Eascra and how manufacturing JBNs in space could one day help millions of people worldwide by providing more effective treatments for some of life’s most difficult health challenges.