« Back to In-Space Production Applications

Crystal Growth

In-Space Production Applications: Crystal Growth

Crystals are the result of consistent layering of atoms or molecules in a regular pattern with symmetrically arranged faces. MicrogravityThe condition of perceived weightlessness created when an object is in free fall, for example when an object is in orbital motion. Microgravity alters many observable phenomena within the physical and life sciences, allowing scientists to study things in ways not possible on Earth. The International Space Station provides access to a persistent microgravity environment. has been used for more than 30 years to improve outcomes of molecular crystal growth. Many researchers, including several from commercial entities, are already using the unique crystallization environment onboard the ISSInternational Space Station National Lab to advance their R&D.

Crystal Growth:

- Organic crystal growth

- Small molecule crystallization

- Large molecule crystallization

- Inorganic crystal growth

- Industrial crystallization

High-quality crystals of organic molecules, such as proteins, can lead to improvements in drug development, formulation, manufacturing, and storage as well as agricultural solutions that better protect crops and enhance plant growth. Proteins—complex molecules consisting of amino acids—are the building blocks of cells and play a crucial role in human health. Crystallization is an important technique for studying macromolecular structure to better understand the function of molecules that are important in health and disease.

More than 60% of all pharmaceutical drugs are crystalline, and changes to the size, shape, structure, and uniformity of the crystals can change the performance of the drug product and the ability to produce it. Crystal uniformity (leading to batch and product uniformity) is a critical element in the production of pharmaceuticals. Not only is crystal uniformity a fundamental part of delivering pharmaceutical products with consistent therapeutic and safety properties but it can also have a significant impact on the production and approval of new and beneficial products, leading to improved economic and health outcomes.

For organic molecule crystallization, the reduction of gravity-driven forces (e.g., convection, sedimentation, and buoyancy) allows molecules to incorporate into the crystalline lattice more slowly and often in a more orderly process that reduces structural defects. Microgravity has been found to produce not only larger and more well-ordered crystals but also crystals of more consistent uniformity.

Why conduct this research in space?

Microgravity can improve crystal growth for numerous applications in drug development, testing, and delivery, as well as inorganic frameworks.

For example, in microgravity, crystals:

Grow in a more uniform manner that can better inform and enable better-quality protein-based therapeutics.

Grow larger and more perfect enabling exceptional-quality industrial crystals and macromolecular structures.

Grow more slowly enabling optical fiber manufacturing that suppresses crystallization defects.

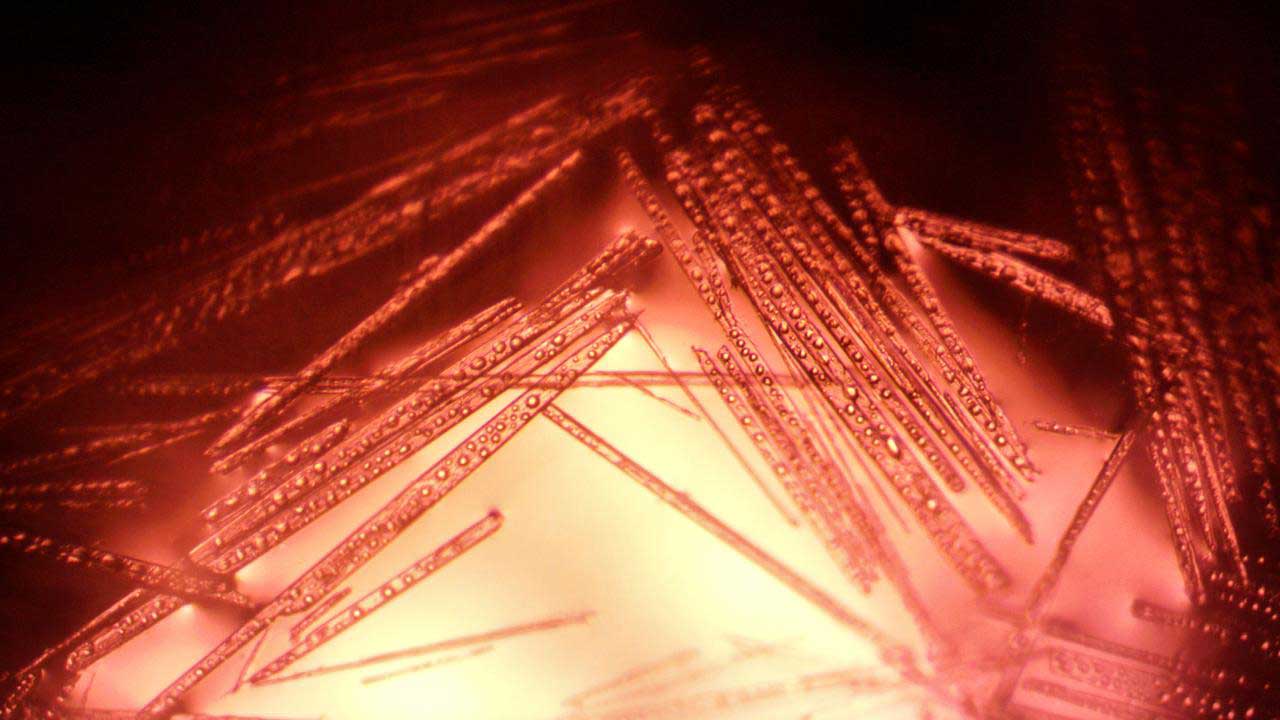

Examples of In-Space Production Applications Organic Crystal Growth Projects

Media Credit: Redwire Space

Small Molecule Crystallization

Small organic molecule crystals represent a majority of all small molecule active pharmaceutical ingredients, but none have been generated on station. This represents a very large opportunity (both in research scale and economic value) and in an area where there is a wealth of existing relevant research.

Media Credit: NASANational Aeronautics and Space Administration

Large Molecule Crystallization

This is a fast-growing and significant area of opportunity in the pharmaceutical industry. Although large molecule proteins have been crystalized in the past (for structure identification of biological target proteins) only one therapeutic product has been crystalized in space: Keytruda®, Merck’s immunotherapy protein-based cancer drug. Unambiguous results demonstrate the potential for other new treatments. Microgravity has been found to produce not only larger and more well-ordered crystals but also crystals of more consistent uniformity. This effect can be translated to pharmaceutical products and products in other industries.

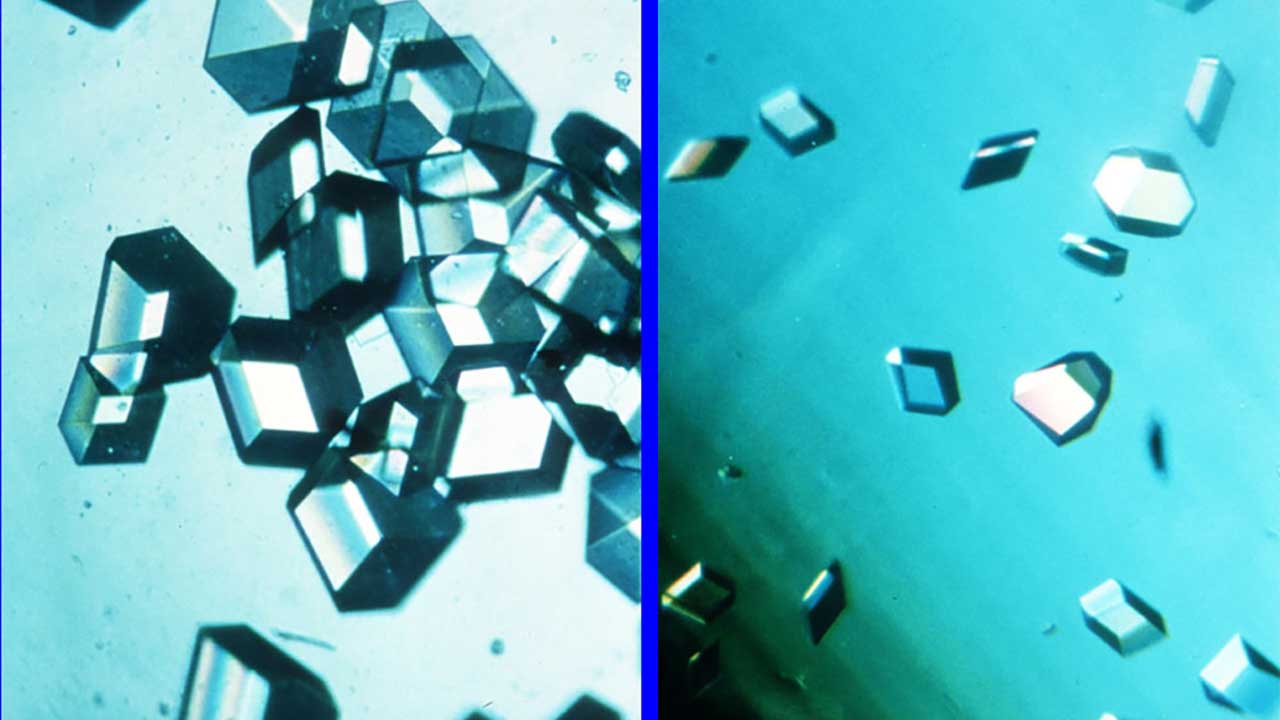

Examples of In-Space Production Applications Inorganic Crystal Growth Projects

Media Credit: NASA

Industrial Crystallization

Industrial crystallization processes on Earth enable the optimized separation, purification, and solid form selection of beneficial products for industrial and pharmaceutical application. On station, these crystals represent a large family of products that promise to impact a broad swath of American industrial sectors. Multiple new commercial facilities for industrial crystallization are being developed and utilized on the ISS now, and early programs have demonstrated the impact microgravity can have in specific systems. Recent studies have focused on large optical crystals, but the field is open for new products and new applications.

High-quality crystallization of large inorganic structures for optics and electronics may help with improved manufacturing and storage and includes projects in radiation detection (semiconductor crystal growth and scintillator crystal growth), metals and optical glasses (alloy solidification with fewer structural defects), and conductive surfaces (i.e., electrode production, thin film deposition).

Various materials including silicon wafers, metals, and inorganic compounds are impacted by the morphology of their crystalline structure. There are many example applications for inorganic crystal growth, including alloying of metals that are susceptible to heavy atom settling, alloys for high-temperature or high-stress environments, crystals of materials that demand high surface area for catalysis, absorption, or molecular design for specific applications. Magnesium and magnesium alloys are an emerging class of lightweight and biodegradable metals with applications in automotive and construction industries and as solutions in regenerative medicine (e.g., bone fracture repair solutions). Crystals of inorganic materials can be used in radiation detection, metal manufacturing, and in the creation of conductive surface (i.e., electrode) production, regenerative medicine, and industrial chemistry.

For inorganic molecule crystallization, microgravity enables crystal growth with less perturbations leading to larger, better-formed structures and potentially better product performance. Improved crystal formation has been seen in metal casting and solution-based crystallization processes. Additionally, microgravity suppresses crystallization in ways that may allow significantly fewer defects in exotic glasses and optical fibers that are difficult to produce on Earth. Microgravity could also improve the structure in crystalline metal ingots and generate larger metal organic framework systems (complex crystalline molecular grids for chemical purification, catalysis, and separations), which represent a significant potential solution for the chemical industry. There are new facilities being developed and utilized on the ISS for industrial crystal growth. Initial studies have focused on large optical crystals, but the field is open for new products and applications.