Contact: Ioana Cozmuta, Ph.D.

Phone: +1 (408) 475-4376

Website: https://www.g-space.com/

Focus Areas: Life Sciences, Physical Sciences, Technology Development/Demonstration

G-SPACE is a software-first, AI-driven platform supporting microgravity research and in-space manufacturing. The platform delivers advanced analytics, optimization tools, and predictive modeling to help investigators and commercial partners design, monitor, and analyze microgravity experiments more efficiently and with greater scientific fidelity.

By converting raw experiment data (images, video, materials characterization, and sensor streams) into actionable insight, G-SPACE reduces R&D time, cost, and operational risk on average by a factor of 10x. Users gain earlier visibility into experiment behavior, improved reproducibility, and clearer pathways to flight-ready and commercially scalable processes.

By providing a specialized, standardized and unified data-science and modeling layer, G-SPACE helps accelerate microgravity research and supports the growth of in-space production.

Scientific Areas of Support

G-SPACE provides hardware-agnostic analytics and generative AI to design what to measure, process microgravity data, and enable iterative experimentation in orbit, turn it into decision-ready insight. The platform supports a wide range of ISS-relevant disciplines, including fluid physics, crystallization, solidification, materials science, biomanufacturing, plant research, and complex multiphase systems. It is the Microgravity Tool featured on the NASA PSI website. Watch a product video or create an account.

Core capabilities include:

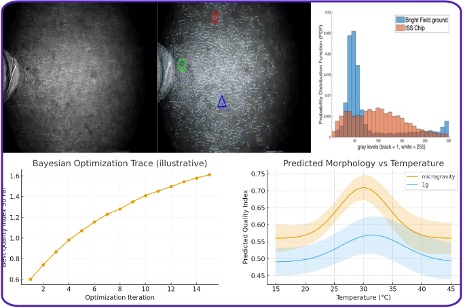

- Pre-flight analytics and imaging design: define and calibrate metrics, data streams, and imaging protocols so identical algorithms can run in flight, compare to terrestrial references, and capture novel morphologies as they emerge.

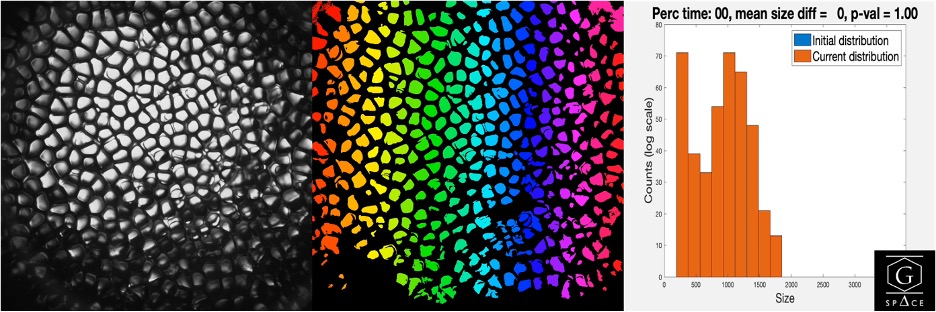

- Automated analysis of microgravity image, video, and sensor datasets: software-driven extraction of morphologies and/or dynamics across partner hardware platforms.

- Computer vision and predictive ML modeling: detect defects, quantify structural properties, and predict process outcomes under varying conditions.

- In-flight monitoring with adaptive decision-support: integrate with camera/sensor payloads to run algorithms in near real time, track key metrics, and recommend adjustments to experiment conditions.

- Post-flight performance analytics, process failure diagnostics and scale-up assessment: analyze why runs did or did not meet targets and evaluate implications for larger-scale manufacturing.

User-Tailored Solutions

Academic Researchers

- Structured ingestion and management of microgravity datasets

- Automated analytical pipelines for imaging, video, and telemetry

- Streamlined tools to quantify microgravity-driven behavior from raw data

- Predictive models to guide experiment design and interpretation

Space Providers & In-Space Manufacturers

- Pre-flight data intelligence planning and process optimization

- Real-time and generative AI analytics for in-orbit monitoring and anomaly detection

- Adaptive product design recommendations during operations

- Post-flight evaluation for quality, reproducibility, and certification

Materials Companies & R&D Organizations

- One-stop microgravity data platform: explore curated datasets to see how materials, fluids, and processes change off Earth

- Visualize, quantify, and benchmark key metrics (morphology, defects, stability, kinetics) across gravity conditions

- Use insights and models to design high-value ISM experiments

- Market and sustainability intelligence to compare ISM pathways and de-risk in-space manufacturing strategies